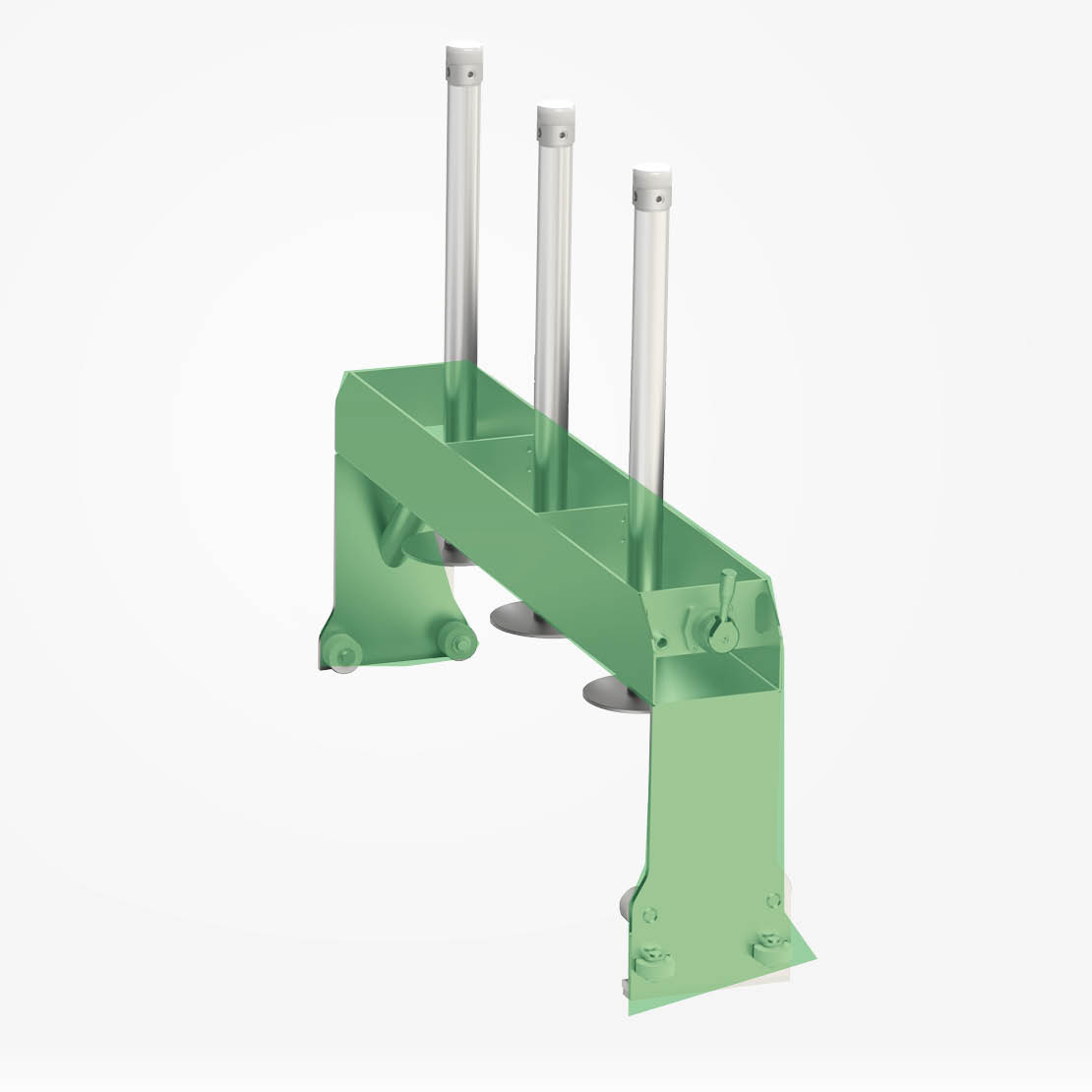

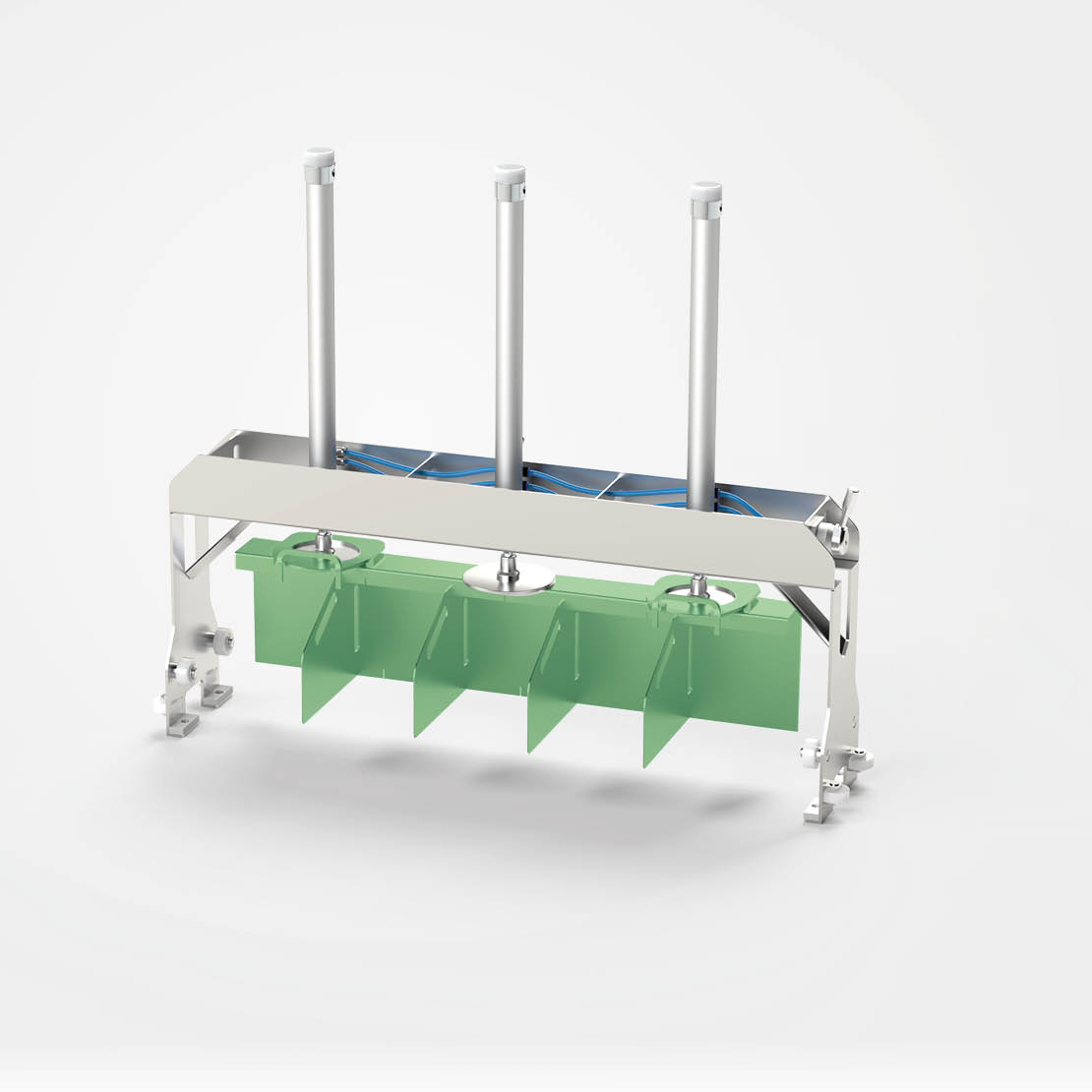

Prepress PRP-R

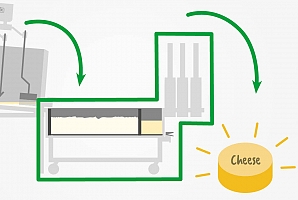

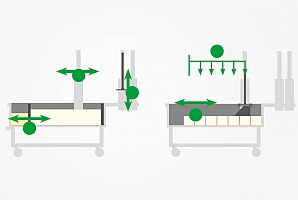

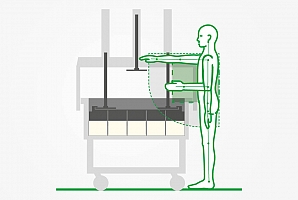

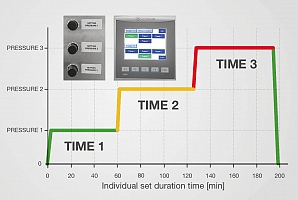

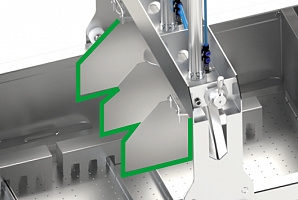

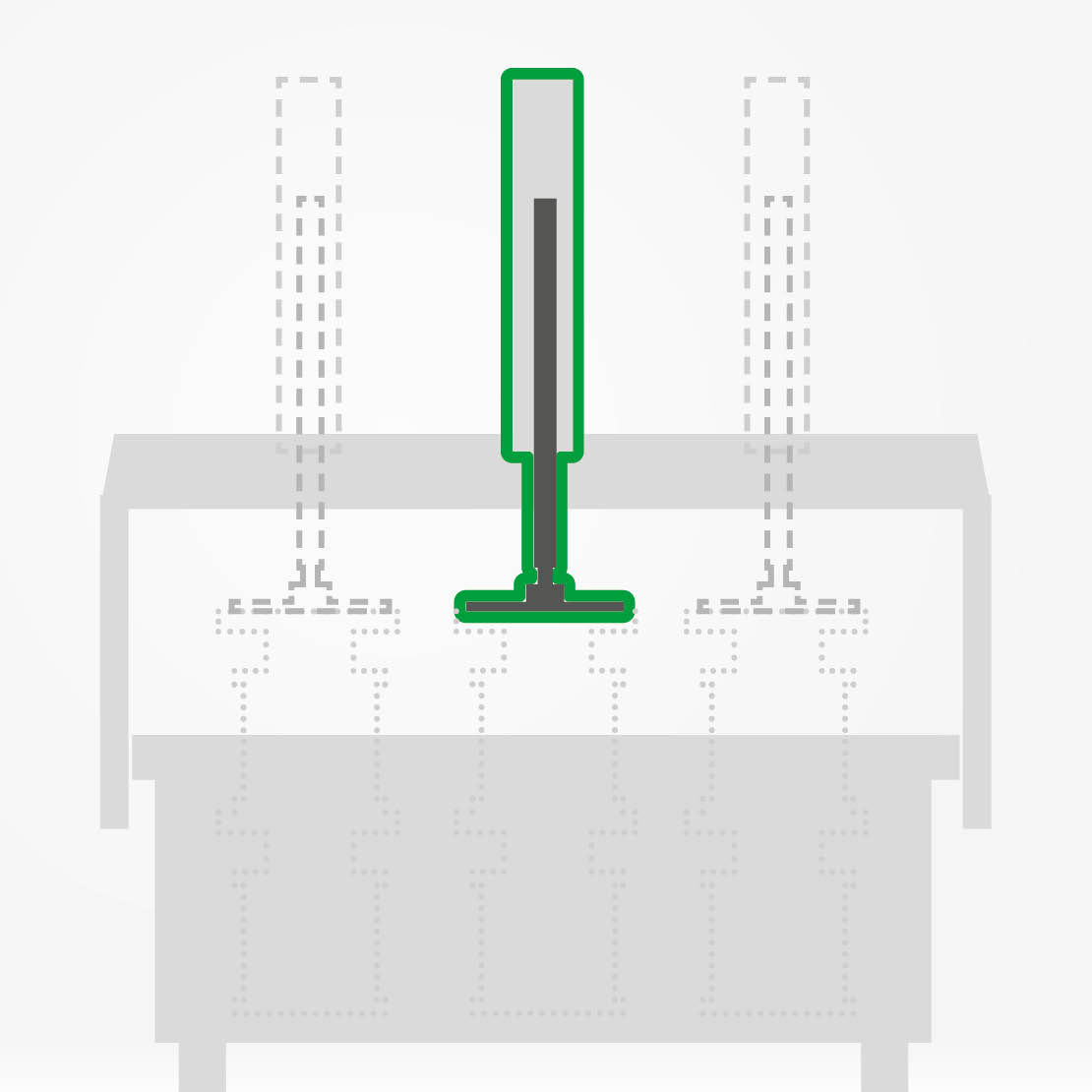

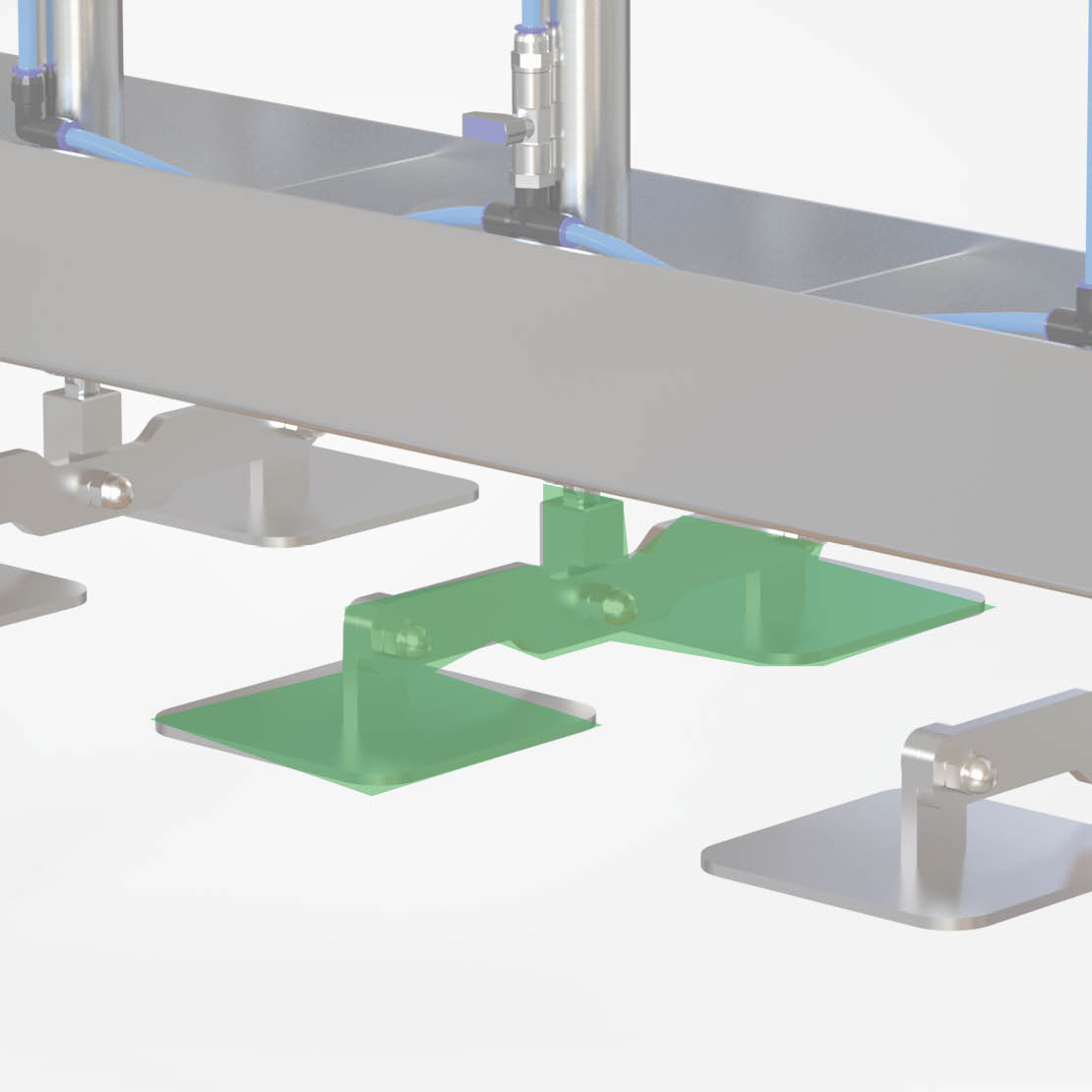

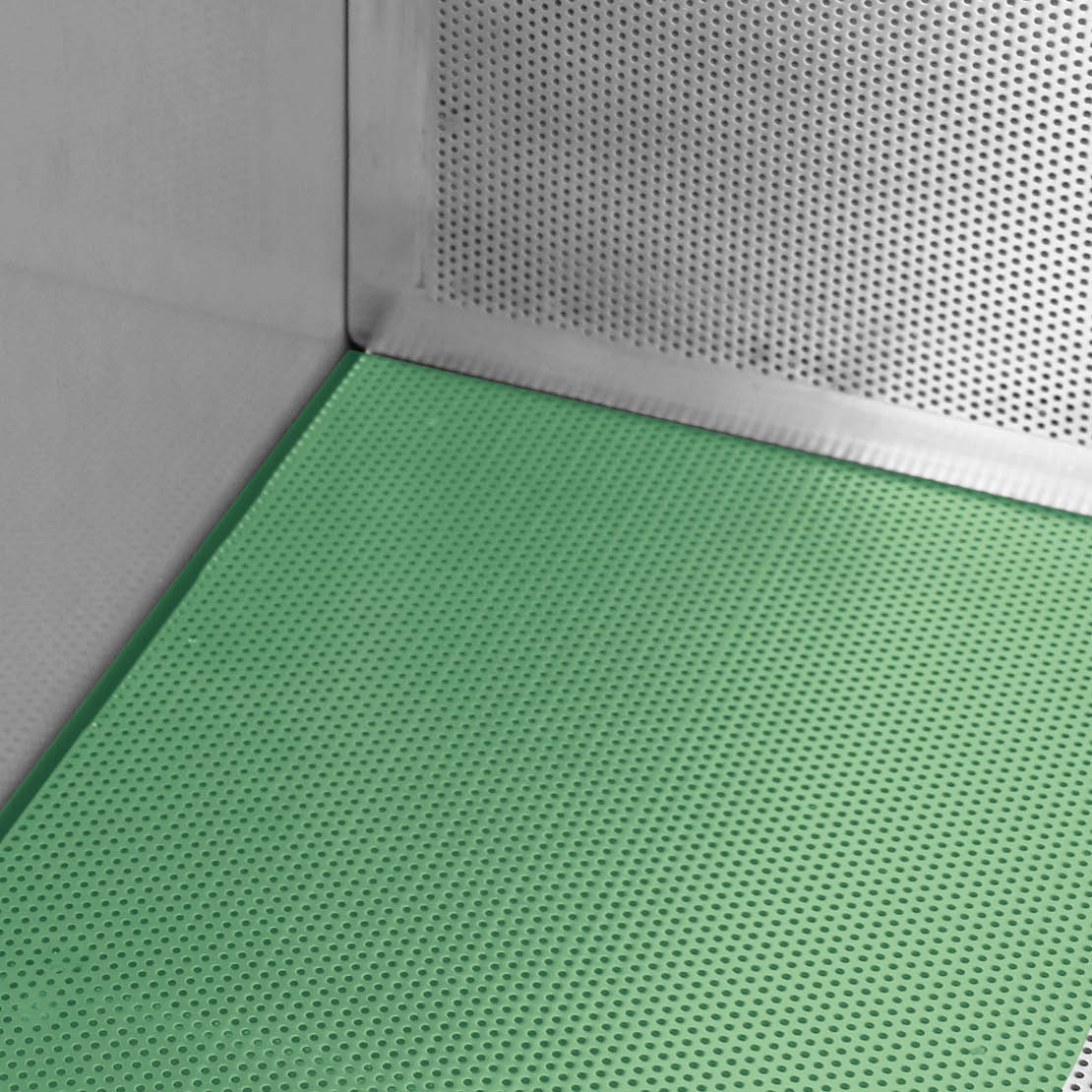

The multipurpose device PRP-R is intended for receiving the cheese mass, draining the whey, prepressing using compressed air, manual cutting of the cheese mass into desired cheese blocks and pressing the mass in cheese moulds. It is distinguished by its wide usability – suitable for making semi-hard and hard cheeses in smaller batches, for making soft cheeses, draining of whey etc.

Advantages

Additional Equipment

Technical Information

More information about capacities, dimensions, number of bridges, …

More informationVideo

Cheese mass processing - with prepress Plevnik PRP-R (universal device)

Operation with Plevnik prepress PRP-R 120 – draining the cheese mass, prepressing and pressing cheese mass in cheese moulds – production of hard cheese.

Dairy: Organic farm Kukenberger, Slovenia

Related videos:

Cheesemaking from 800 liters of milk with Plevnik cheese kettle SKH 1000 EW PRO and prepress PRP-R 120Cheese making - cutting cheese mass with new PRP-R cutting module