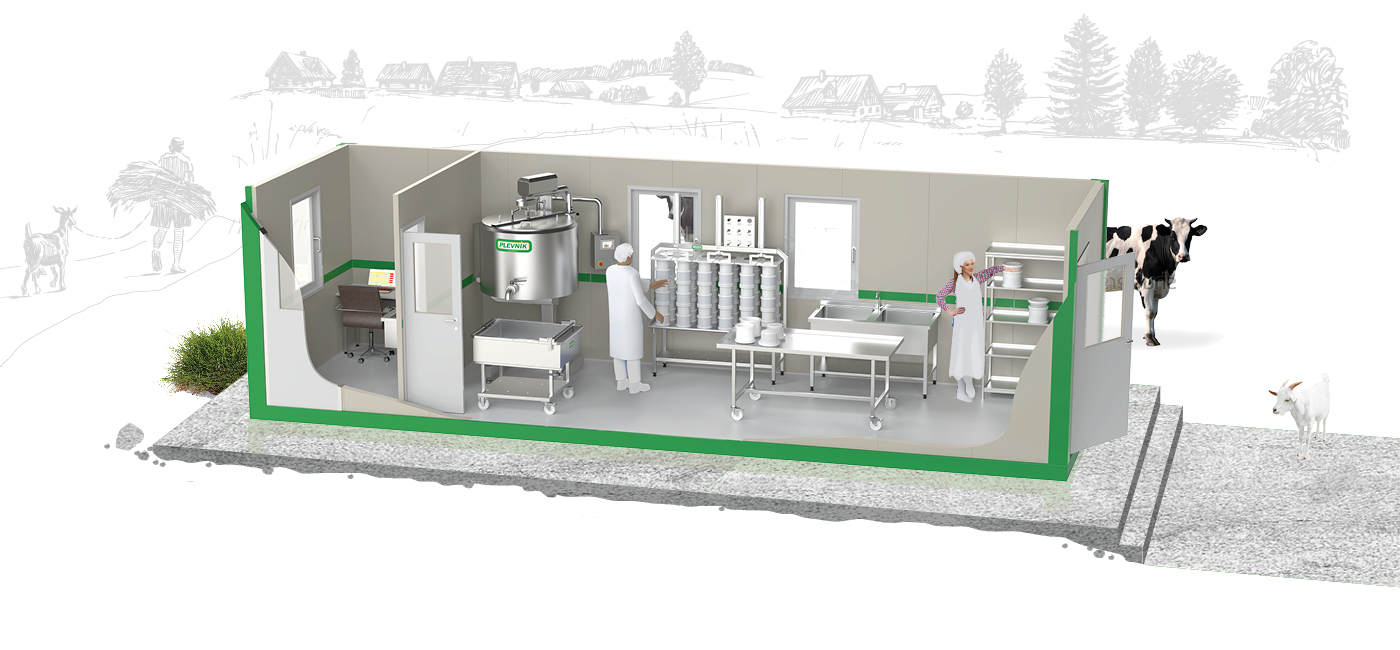

Container solution – turnkey dairy SMMO

Turnkey dairy is a modular block of containers equipped with dairy equipment. Containers are usually split to different working parts (warderobe, office, dairy, maturation, etc). We can add maturation room, cooling room, warehouse, shop… to basic container. All equipment complies with HACCP standards, that are made from food safe materials. Electrical installations are carried out with the protection class IP55. It has a built-in system for electrical heating and ventilation system by sensing the moisture. Ceiling height is 2.5 meters, wall thickness is 100mm (0.36 W / m2K), the floor has 150mm of insulation (0.24 W / m2K), the roof has 200mm of insulation (0.19 W / m2K), glazing of the windows and doors is double-layered (Ug = 1.1 W / m2K).

Advantages

Versions

SNK 100

25 m2, 100 litres of milk/batch

Product: fresh cheese / joghurt / curd / butter / …

SNK 300 Advanced

32 m2, 300 litres of milk/batch

Product: soft cheese / semi hard cheese /hard cheese / joghurt / ricotta / grilled cheese / curd / …

SNK 500 Professional

50 m2, 500 litres of milk/batch

Product: soft cheese / semi hard cheese /hard cheese / joghurt / ricotta / grilled cheese / curd / …

SNK 500 Premium

50 m2, 500 litres of milk/batch

Product: soft cheese / semi hard cheese /hard cheese / joghurt / ricotta / grilled cheese / curd / …

CONTAINER MODULES DAIRY:

D3: 7,3 x 2,4 x 3 m, net: 16 m2

D3W: 7,3 x 3 x 3 m, net: 20 m2

D4: 9,1 x 2,4 x 3 m, net: 20 m2

D4W: 9,1 x 3 x 3 m, net: 25 m2

CONTAINER MODULES COLD STORE/RIPENING ROOM:

M1: 4,6 x 2,4 x 3 m, net: 9 m2

M1W: 4,6 x 3 x 3 m, net: 12 m2

M2: 6,1 x 2,4 x 3 m, net: 12 m2

M2W: 6,1 x 3 x 3 m, net: 16 m2

M3: 7,3 x 2,4 x 3 m, net: 15 m2

M3W: 7,3 x 3 x 3 m, net: 19 m2

M4: 9,1 x 2,4 x 3 m, net: 18 m2

M4W: 9,1 x 3 x 3 m, net: 24 m2

Additional Equipment

Technical Information

More information about types, versions, dimensions, connections, outlets, …

More informationVideo

Container solution for turnkey dairy

Order now … Start tomorrow! Without a building permit. Faster to build than traditional construction (20-times faster). Affordable investment Fully equipped. No additional costs. Think business, the rest is included. Minimal ground work. Built according to HACCP standards. Flexible solutions allow expansion: maturation chamber, shop, packaging etc.