PN 500 E and PN 500 E+ are suitable for users who want to replace manual filling with automatic filling. They can be used to fill milk, whey, yogurt and fruit yogurt (with fruit particles up to 6 mm and hard particles up to 4 mm). They are intended for filling dairy products with a viscosity of up to 2,600 CPs.

PN 500 E Adv and PN 500 E Adv+ are suitable for advanced users who fill milk, whey, yoghurt and fruit yoghurt (with fruit particles up to 10 mm and hard particles up to 8 mm) and other products. The pump works very gently on the products so that it perfectly maintains the quality of the product. The pump is easy to clean and allows for easy maintenance. It is intended for filling dairy and other products with a viscosity of up to 16,000 CPs.

• 4,3″ color touch screen

• Volume adjustment from 0.1 l

• Display with time

• Quick access to programs

• Built-in filling counter

Charging programs: 6 arbitrary programs for different media or filling volumes.

Setting options: filling time, filling frequency, arbitrary naming of programs, …

Mixing program 1: starts working when the button is pressed and stops filling when the button is pressed again.

Manual program 1: is filling when the button is activated. When the button is released, the filling stops.

* The filling tolerance depends on the viscosity of the product (1 to 3%).

** Accessories

Plain yogurt

Milk

Whey

Yogurt is poured from the kettle directly into the hopper, where it can be homogenized by hand with a hobby dispersion mixer. Alternatively, pumping starts immediately and homogenization is carried out with the help of the homogenization attachment, which is installed before the outlet of the filler.

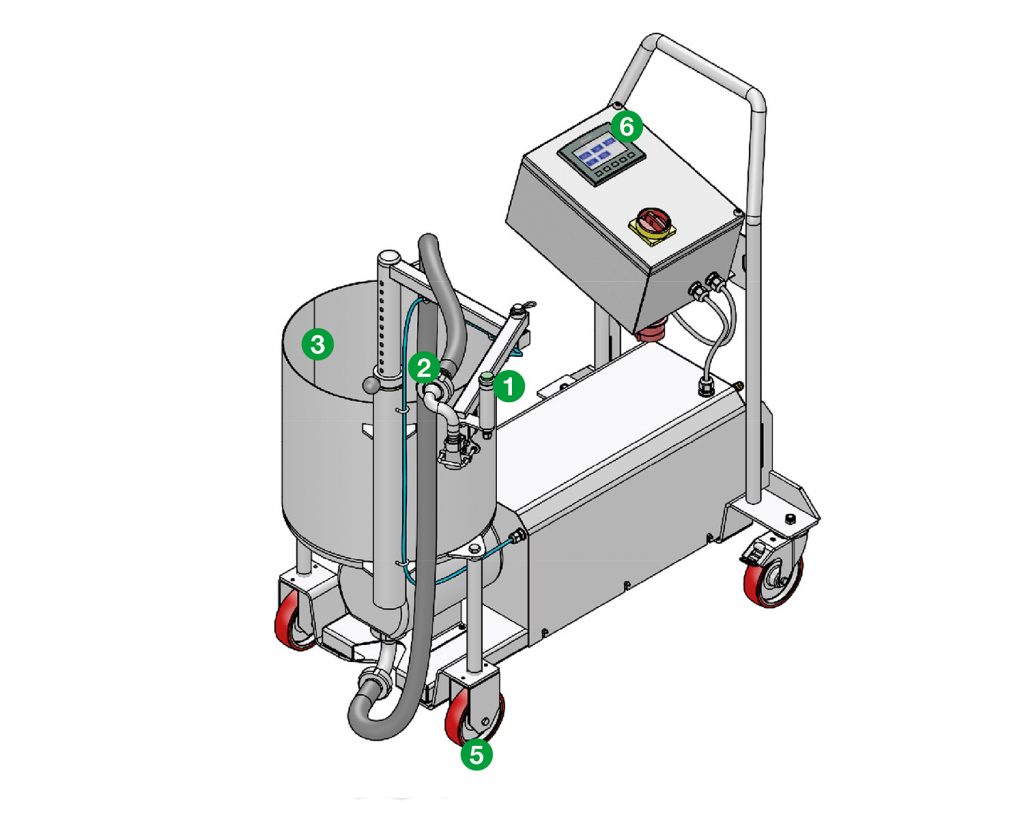

The pump pumps the yogurt to the dosing arm. The arm is designed to allow easy movement in all directions (forward, backward and vertically – depending on the height of the pots). It allows the user to pre-place pots or bottles on the cheese table. Then the filling arm moves freely from bottle to bottle. The dosing volume can be set on the controller. Filling is initiated with a button on the filling arm, which results in the dosing of the set volume.

Fruit yogurt

Yogurt is poured from the kettle directly into the hopper, where it can be homogenized by hand with a hobby dispersion mixer. When the plain yogurt is homogeneous, we can add the fruit base to the container. It is mixed with a hobby dispersion mixer to obtain a uniform, homogeneous fruit yogurt in the hopper. Then we start filling.

The pump pumps the yogurt to the dosing arm, which is designed to allow easy movement in all directions (forward, backward and vertically – depending on the height of the pots). It allows the user to pre-place pots or bottles on the cheese table.

Then the filling arm moves freely from bottle to bottle. The dosing volume can be set on the controller. Filling is initiated with a button on the filling arm, which causes the set volume to be dispensed.

Contact us and we will be glad to answer all your questions

Add value to milk.

PLEVNIK

engineering and production, d.o.o.

Podsmreka 56,

1356 Dobrova, Slovenia

Phone: +386 1 200 60 80

Subscribe to our newsletter to receive exclusive offers and the latest news about our products and services.

2020 © Plevnik, d.o.o., All rights reserved.

In the process of constant improvements, we reserve the right to make technical and design modifications without prior notice. Pictures are simbolic.