Conversion of waste energy

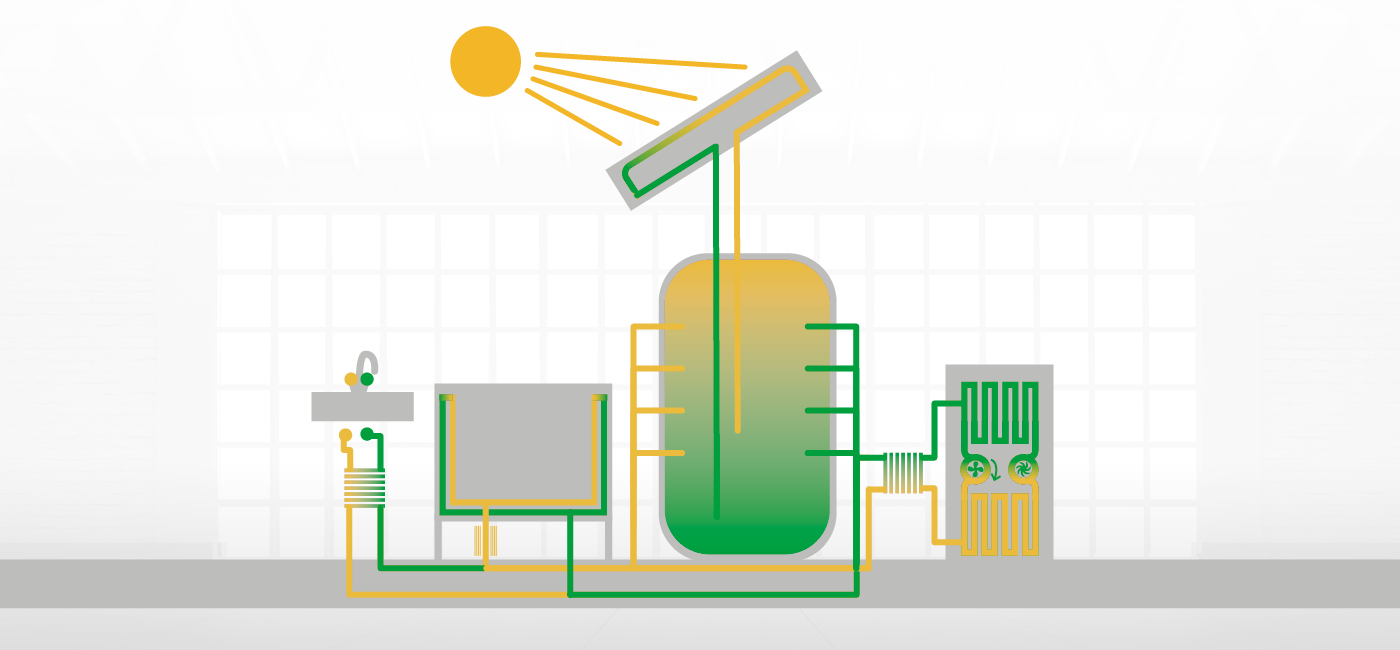

Energy recovery during the cooling of milk after the process of thermal treatment

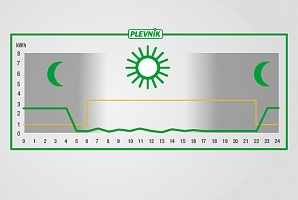

Examples of heating the water in the storage tank during the cooling of milk after the pasteurization (64°C -> 24°C – ΔT=40°C) and after the making of ricotta (93°C -> 24°C – ΔT=69°C). We can use the hot water the next day to heat again the milk. Using this system we can save in electricity / gas / oil for heating the milk.

Advantages

Heating Options

Different heating options are available:

Technical Information

More information about types, heating power according to version, dimensions, cooling and hot water connections, weight, outlets, …

More information

HW - Hot water

HW - Hot water EL - Electricity

EL - Electricity EW - Combination

EW - Combination ST - Steam

ST - Steam