Cabinet for cheese ripening OZS 700-1400

Cabinet for cheese ripening OZS 700 and 1400 are thermal (from 5°C to 18 °C) storage units, used for cheese ripening processes. Because of the controlled temperature and humidity system, the cabinet creates an ideal climate for controlled and repeatable ripening of cheese. The OZS is durable, reliable, efficient, and easy to use (no experience needed.) A ripening room with controlled conditions, right where you need it. For example in your shop.

Advantages

Additional Equipment

Technical Information

Cabinet for cheese ripening OZS 700

Temperature range: 5 – 18 °C

Electronic thermostat for cooling control

Electronic humidity control* (50-95% RH)

AISI 304 stainless steel inner and outer liner

Cooling system in monoblock version at the top of the cabinet

Dynamic cooling

60 mm polyurethane insulation

Self-locking door with magnetic seal

Leveling legs

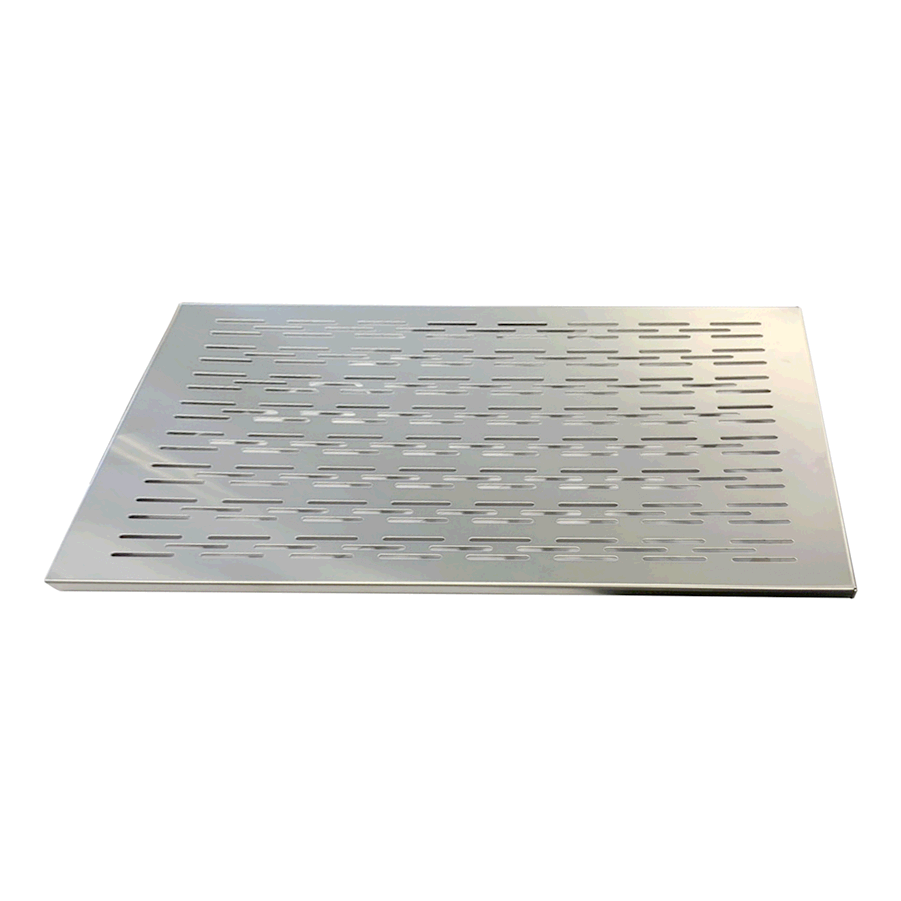

Number of shelves: 4 (perforated inox grid, 650×530 mm)

Max. number of shelves: 10 (120 mm spacing)

Coolant: R452a

Power supply: 230V / 50Hz, 390 W

Dimensions: 710 x 800 x 2050/2100 (WxDxH)

Weight: 110 kg

Cabinet for cheese ripening OZS 1400

Temperature range: 5 – 18 °C

Electronic thermostat for cooling control

Electronic humidity control* (50-95% RH)

AISI 304 stainless steel inner and outer liner

Cooling system in monoblock version at the top of the cabinet

Dynamic cooling

60 mm polyurethane insulation

Self-locking door with magnetic seal

Leveling legs

Evaporation of condensed water

Number of shelves: 8 (perforated inox grid, 650×530 mm)

Max. number of shelves: 20 (120 mm spacing)

Coolant: R452a

Power supply: 230V / 50Hz, 570 W

Dimensions: 1420 x 800 x 2050/2100 (WxDxH)

Weight: 180 kg

*Cabinet basic humidity controller allows the user to adjust and observe relative humidity. The dehumidification is automated. Higher relative humidity is achieved by adding a plain container with water or wet clay slab on the bottom of the cabinet.

More information