Automated cheese prepress PRP-AP

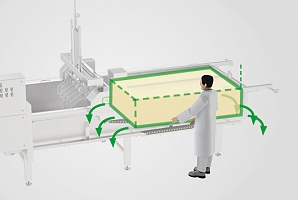

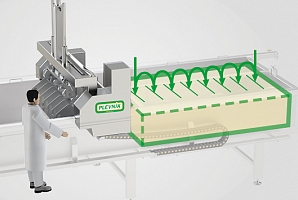

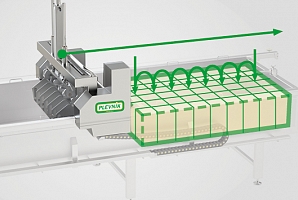

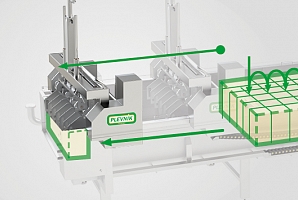

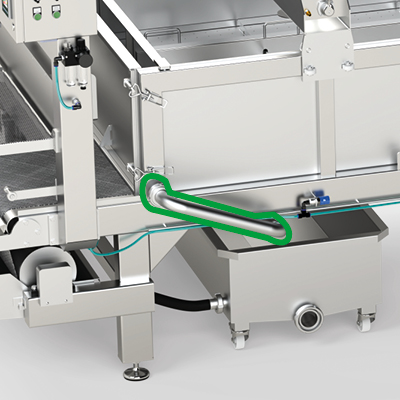

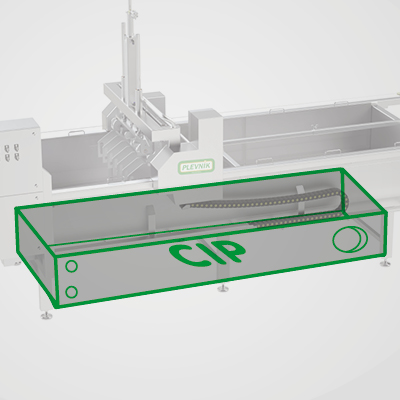

Cheese prepress PRP-AP is automated, user-friendly prepress with adjustable programs for automated pressing and cutting. This multipurpose device is intended for receiving the cheese mass, draining the whey, automatic prepressing using compressed air, automatic or manual cutting of the cheese mass into desired cheese blocks and automatic pressing of cheese mass in cheese moulds. It is distinguished by its wide usability – it is suitable for making semi-hard and hard cheeses in smaller batches from 1.000l up to 4.000 l.

Plevnik prepresses enable better quality control of cheese and excellent yield -approximately 10 % cheese mass from the source quantity of milk.

Advantages

Additional Equipment

Technical Information

More information about possibility of processing cheese mass, pressing points, cylinders, dimensions, working height, …

More informationVideo

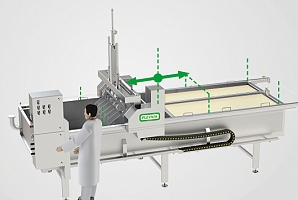

Plevnik prepress PRP-AP: Complete automatization

Operation with Plevnik prepress PRP-AP – draining the cheese mass, prepressing and pressing cheese mass in cheese moulds – production of hard cheese.