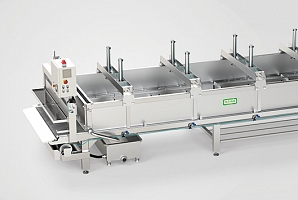

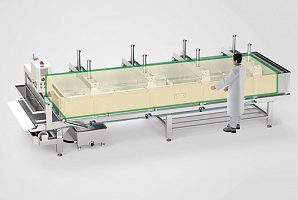

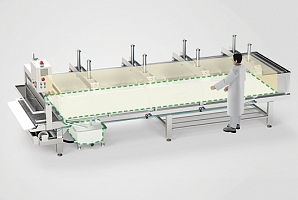

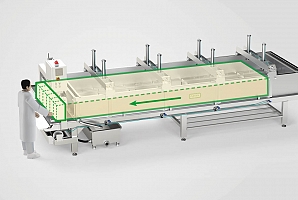

Cheese prepress with transport belt PRP-RT

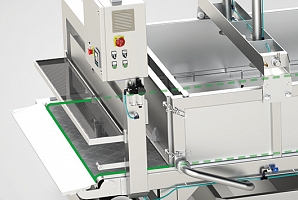

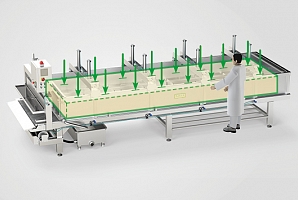

- Prepress with a draining transport belt, movable bridges and cutting knives at the front of the vessel.

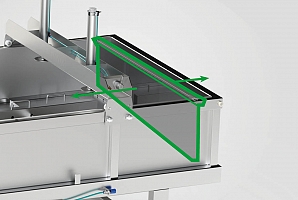

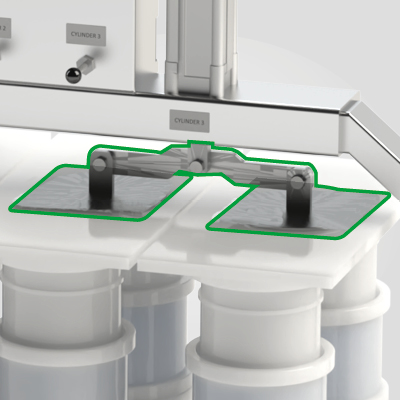

- Movable bridges enable different arrangements of bridges along the table, depending on the processed quantity of cheese mass.

- Simple manual regulation of prepressing with movable bridges.

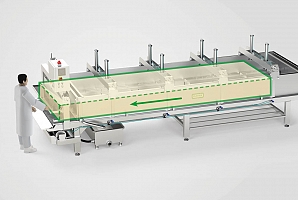

- Transport belt enables cutting of cheese mass and conveying of cheese blocks, which enables a faster and more productive workflow.

Advantages

Additional Equipment

Technical Information

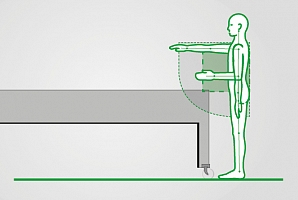

More information about possibility of processing cheese mass, pressing points, cylinders, dimensions, working height, …

More informationVideo

Cheese making 5000 l - cheese prepressing with Plevnik PRP-RT device

Demonstration of making semi-hard cheese with the equipment – Plevnik cheese cistern SCH 2000 C on platform – Plevnik cheese pre-press PRP-R with automatic pressure control