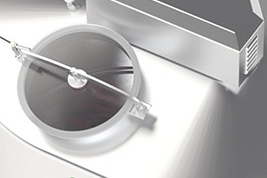

Cheese vats and cisterns SKH/SCH 2O 500–5000 l

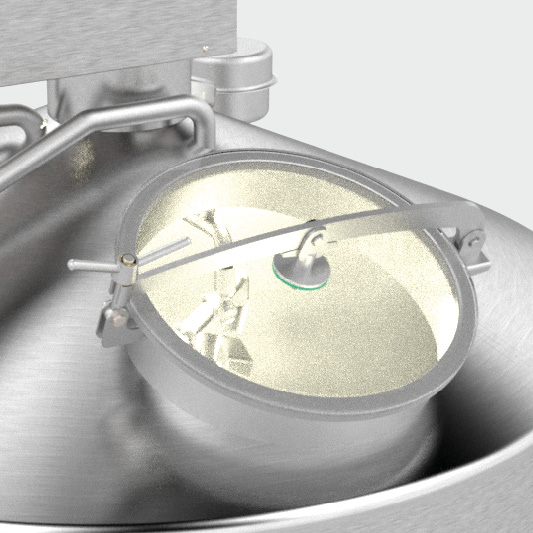

Cheese vats SKH and cisterns SCH 2O are used for thermic processing of larger quantities of milk (500–5.000 liters) into various dairy product, such as: cheese, curd, ricotta, yogurt, pasteurized milk, … They enable thermic processing of milk in the range between 4 °C and 100 °C. Plevnik cheese vats and cisterns are made in accordance to international standards, CE directives and the latest findings in dairy industry. They are created for making extraordinary dairy products and for modern and successful cheesemaking stories.

Advantages

Heating Options

Different heating options are available:

Versions

Two versions are available: SKH – cheese vat which is an open execution, and SCH – cheese cistern which is a closed execution.

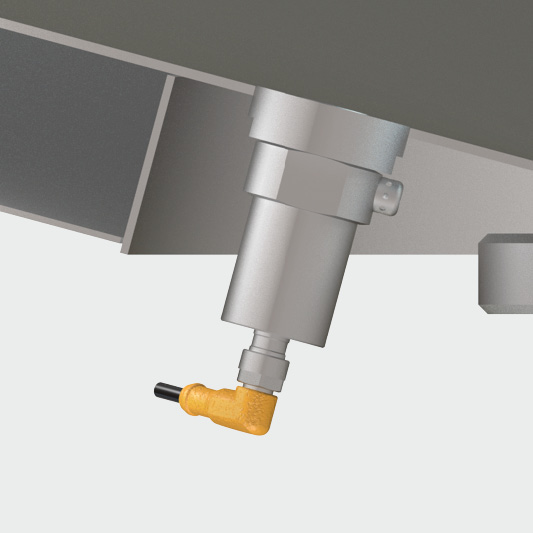

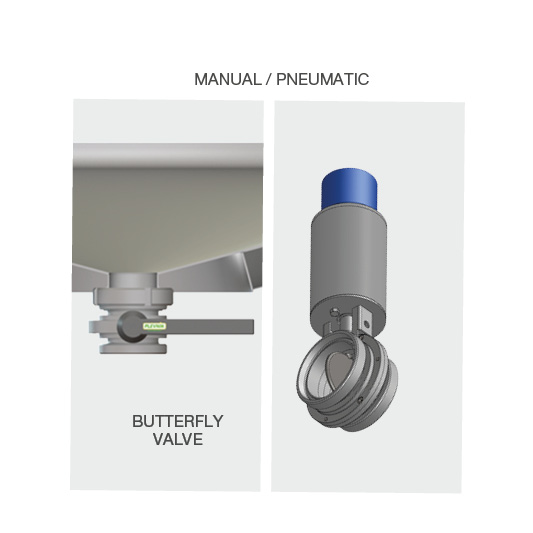

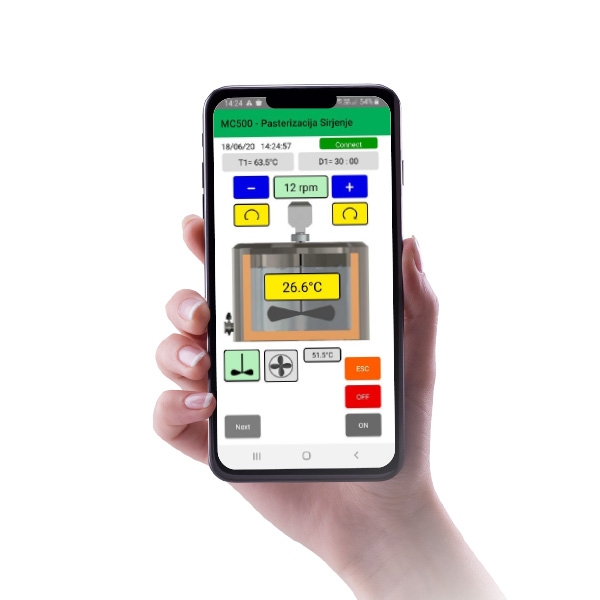

More informationAdditional Equipment

Technical Information

More information about dimensions, outflows, water connections, power, …

More information

HW - Hot water

HW - Hot water EL - Electricity

EL - Electricity EW - Combination

EW - Combination ST - Steam

ST - Steam