Mechanical draining prepress MOS 50

The mechanical draining press is a multi-functional device with three functions in one device: draining, prepressing, and pressing of the cheese mass. The perfect choice for a cheesemaker that needs a high-quality device to make all kinds of cheese, drain curd or greek yogurt … A great solution for diverse batches up to 500 l of milk. It is made entirely of stainless steel AISI 304. MOS 50 does not need electric energy or compressed air to work. For prepressing and pressing, MOS 50 uses weights.

Advantages

Additional Equipment

Technical Information

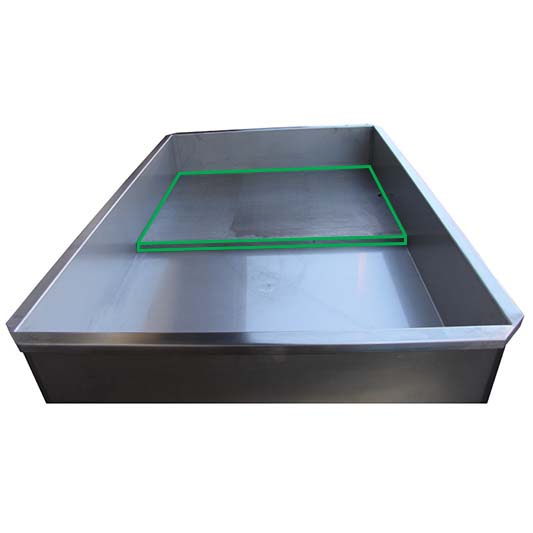

Approximate processing capacity 50 kg of cheese curd. Expected height of the cheese curd:

100 mm

Material: parts that come in contact with the product are made of stainless steel W.Nr.1.4301

(AISI 304).

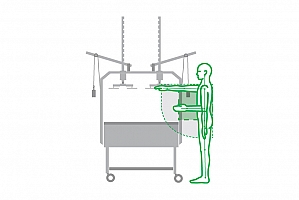

Dimensions (LxWxH) – for installation: 1120 x 680 x 2220 mm, vessel inside: 1000 x 580 x 300

mm (from floor – to upper edge: 850 mm)

Working height 800 mm.

Description and contains:

• deepened (300 mm) cheese table for accepting the cheese mass with whey

• outflow valve for whey

• two draining grids (movable on the front and fixed on the back)

• self-supporting construction with a frame over the draining table

• weights for determining pressing force (10-92 kg on pressing point)

• two (2) pressing points

• plates for prepressing (segments)

• support on wheels