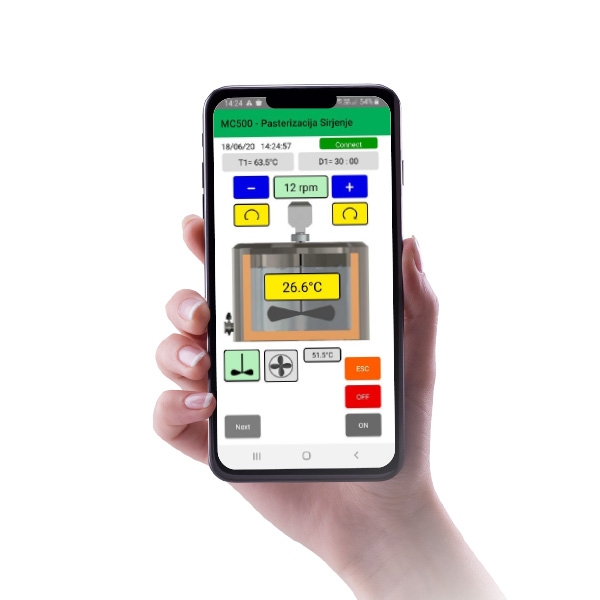

Cheese kettles with copper inside SKH-Cu 300–1500 l

SKH-Cu is a cheese kettle SKH with copper inside. Copper is a traditional material, used in cheesemaking – it has been used for a long time, mostly in the Alps. You can produce products in a traditional way using modern equipment. It is suitable for production of different types of cheeses with a special, traditional flavour. We recommend heating for up to 63 °C.

Advantages

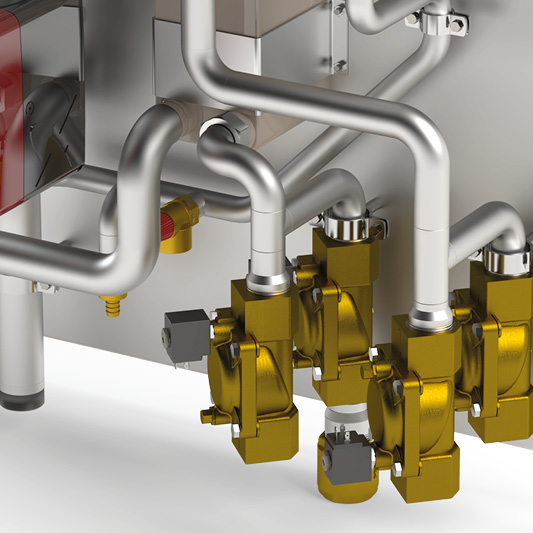

Heating Options

Different heating options are available:

Additional Equipment

Technical Information

More information about types, heating power according to version, dimensions, cooling and hot water connections, weight, outlets, …

More informationVideo

Cheese kettle with copper inside SKH-Cu 1000

Demonstration of work with Plevnik cheese kettle with copper inside – SKH-Cu.

HW - Hot water

HW - Hot water EL - Electricity

EL - Electricity EW - Combination

EW - Combination