Cheese kettle with cooling/heating unit SKH-H 200-650 l

SKH-H is a SKH Cheese kettle with a standalone heating and cooling unit. It is all in one device: pasteurizer/cheese/kettle/cooling tank/fermentation vessel. It enables thermic processing of milk in the range between 4 °C and 100 °C. It can be used for milk pasteurization and for production of dairy products such as soft, semi-firm or hard cheese, butter, yoghurt, curd, sour cream…

Buy only one machine to make all your dairy products – and it can be used also as a milk cooling tank!

Advantages

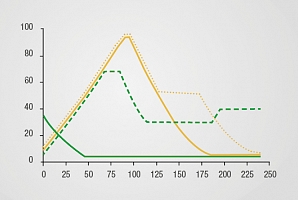

Heating Options

Different heating options are available:

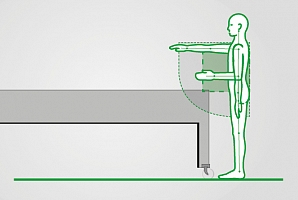

Versions

Different versions of cheese kettles SKH are available: from more simple versions to professional cheese kettles for advanced users. Individual versions have different heating options and different equipment possibilities.

More informationAdditional Equipment

Technical Information

More information about types, heating power according to version, dimensions, cooling and hot water connections, weight, outlets, …

More information