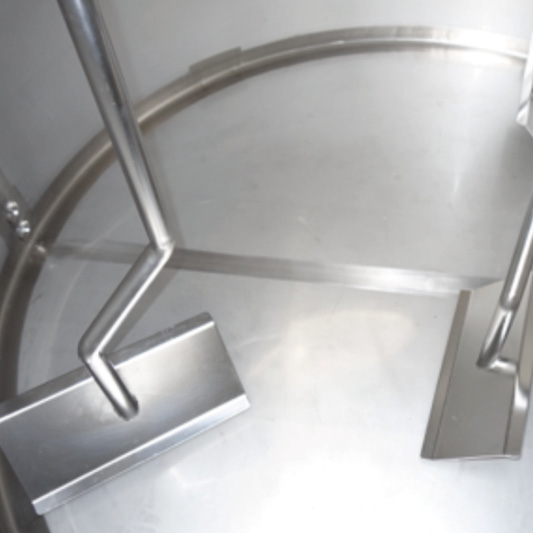

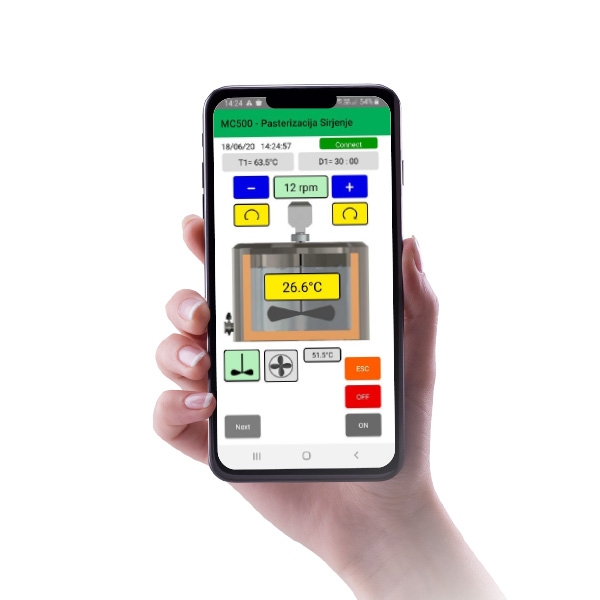

Cheese vats and cisterns SKH/SCH 1000–4000 l

Cheese vats and cisterns are used for the thermic processing of medium quantities of milk (1.000–4.000 liters) into dairy product, such as: cheese, curd, ricotta, yogurt, pasteurized milk, … They enable thermic processing of milk in the range between 4 °C and 100 °C. Plevnik cheese kettles are made in accordance to international standards, CE directives and the latest findings in dairy industry. They are created for making extraordinary dairy products – for modern and successful cheesemaking stories.

Advantages

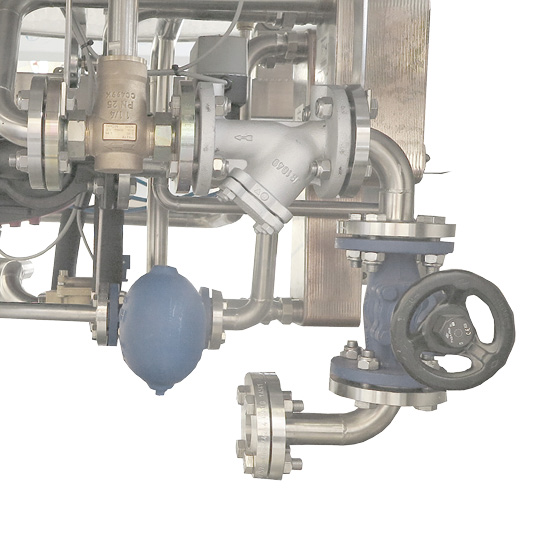

Heating Options

Different heating options are available:

Versions

Two versions are available: SKH – cheese vat which is an open execution, and SCH – cheese cistern which is a closed execution.

More informationAdditional Equipment

Technical Information

More information about types, heating power, dimensions, weight, …

More informationVideo

Semi-hard cheese production

Production of semi-hard cheese with Plevnik cheese vat SKH 1000 C and cheese draining table SOM 209.

HW - Hot water

HW - Hot water ST - Steam

ST - Steam