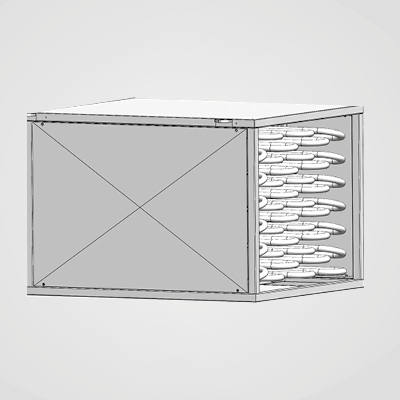

Flow pasteurizer PP 500–3000 l

Plevnik flow pasteurizer is used for continuous pasteurization of larger quantities of milk (HTST pasteurization – high temperature, short time). Pasteurization stops the vital activities of pathogenic form of bacteria and is essential in milk processing. Pasteurized milk can be further processed into various dairy products, such as cheese, yogurt, …

Advantages

Heating Options

Different heating options are available

Versions

Different versions of flow pasteurizer PP are available: from more simple versions to professional flow pasteurizers for advanced users. Each version has different equipment possibilities.

More information

HW – Hot water

HW – Hot water EL – Electricity

EL – Electricity ST - Steam

ST - Steam